You’re likely to have spotted an old mattress slumbering by the roadside, and they’re an environmental nightmare. Here are two Australian’s with an innovative solution.

Learn how old mattresses can be recycled into household benchtops, splashbacks and flooring in this resource for Year 7 and 10 STEM students.

Word Count: 644

Old mattresses are ubiquitous.

You see them slumbering on roadsides everywhere, or sleepily propped up next to charity bins. Mostly they come to rest in tips.

They are a global environmental nightmare.

But Andrew Douglas has found a way of making mattresses gold.

His company, Mattress Recycle Australia, is based in the regional New South Wales town of Cootamundra and it services all of the state.

“Recycling is quite profitable,” he says. Councils and individuals pay him to collect mattresses and MRA shreds them.

“At the moment we’re obviously able to extract the steel, which steel merchants and the steel mill up at Newcastle are willing to pay a reasonable amount of money for.”

But there was one thing that troubled him.

“Our issue had been what to do with the textile component.”

Until, nearly nine years ago, Andrew met Veena Sahajwalla at a sustainability conference in Wollongong.

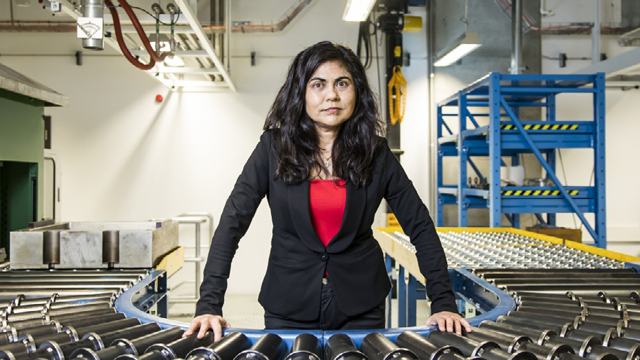

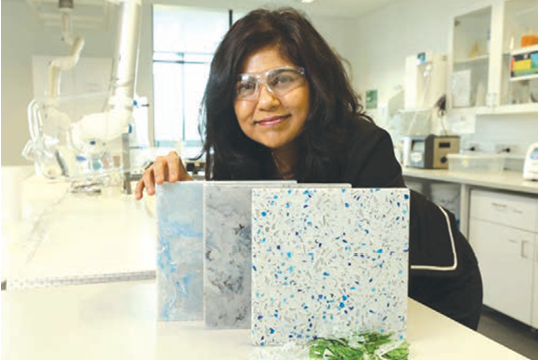

Professor Sahajwalla is an inventor and engineer who’s passionate about turning waste into a resource.

She is the Director of the Sustainable Materials Research and Technology Centre at the University of New South Wales and pioneered world-first ‘green steel’ technology, where hydrogen and carbon are extracted from waste rubber to make metal.

Andrew says he approached her with his problem: what to do with the material left over from recycling his mattresses.

I said “Look, this textile, it’s just building up in landfill. We’ve really got to think outside the box.”

She said “Let me take some samples. I’ll take it back to my team and I’ll come back to you.”

Two years later she did.

“They had some prototype tiles that looked really pretty,” Andrew says.

The SMaRT Centre team had developed modular technology and trade-marked it as ‘MICROfactorie’.

It is able to produce a range of products for the built environment from types of waste glass and textiles that are traditionally not subject to recycling.

Mattress Recycle Australia is now using the technology and is in discussions for a commercial arrangement with the University.

Andrew sees the potential for making benchtops, splashbacks and flooring.

His plant combines the fabric from old mattresses with finely-crushed glass from beer bottles, and mixes the material with a binder before pressing it into tiles.

“We thought, there’s a concept here that we should pursue. So we’ve had a few evolutions of the tile. And now we’ve got to a point where we can commercialise them.”

“Our process is quite simple. There’s a lot of tech involved, and a lot of science in the background, but the actual process is quite straightforward.”

He says the tiles have the equivalent strength of Caesarstone.

“From our perspective it performs as well or better than anything on the market at the moment.”

The Academy of Technology and Engineering became aware of the product when it was producing its Towards a Waste Free Future report last year.

The tiles were also featured in an Australian Story profile of Professor Sahajwalla on ABC Television.

Andrew says since then he’s had around four thousand enquiries from people wanting to know more.

One of those enquiries came from ATSE which was in the process of moving into new Canberra offices and refurbishing the kitchen.

The recycled tiles were installed as the office kitchen splashback.

Andrew came to see them in situ when the new office was officially opened in April.

“This is our first commercial install,” he says, stroking the tiles with a proprietary air.

“We’re very proud that we’ve got some early adopters here to showcase the green ceramics.”

He says he’s also in advanced talks with industry partners, like property group Mirvac, to explore the best way to harness and implement the great sustainability credentials of the product.

It’s been a whirlwind few months.

“Now we’ve closed the loop, we’ve got this solution,” he says.

Where next?

“We’re looking to go to the stars!”

Written by Liz Foschia, Communications Manager, ATSE.

This article is reproduced with the kind permission of Liz Foschia, ATSE.

Years: 7, 10

Login or Sign up for FREE to download a copy of the full teacher resource